In infrared thermography measurements, the thermal camera converts the invisible (to the eye) infrared radiation emitted by the object under test into a visible image. The thermal camera is in fact a spectral radiometer that measures the radiant energy emitted and, with appropriate calibration and considerations, can infer the temperature distribution of the surface under investigation. The advantages of thermographic temperature measurement:

a. fast

b. non-contact and safe (no dangerous radiation, but requires high power external excitation shields for the duration of the flash)

c. results are relatively easy to interpret

d. wide applicability

e. often the only non-contact test device

Thermographic measurements can be divided into two broad categories based on the measurement setup:

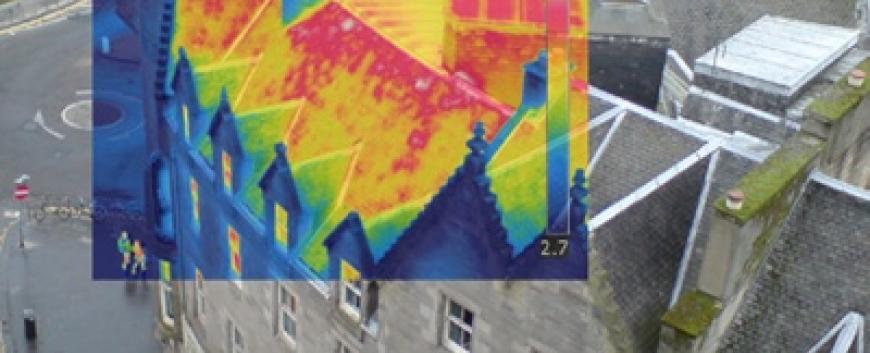

a. Passive thermography: the temperature of the materials or structures to be tested differs naturally, "by itself", from the temperature of the environment

b. Active thermography: an external excitation is required to induce the relevant temperature contrast, which can be in a reflection or transmission configuration

Potential areas of application:

1. Industrial and electrical equipment diagnostics

2. Detection of hidden material defects

3. Building thermography

4. Leak detection

5. Machine vision

Main research areas:

1. Pre-processing of thermal images, image sequences: smoothing, filtering and further processing.

2. Quantitative evaluation of thermal images: set-up and numerical solution of inverse thermal models to determine certain material properties (e.g. thermal conductivity, heat capacity, etc.).

3. Thermal imaging of semitransparent materials: e.g. study of the flow pattern of gases emitted in the detection range of the detector

CONTACT

Pécsi Tudományegyetem | Kancellária | Informatikai és Innovációs Igazgatóság 2021.